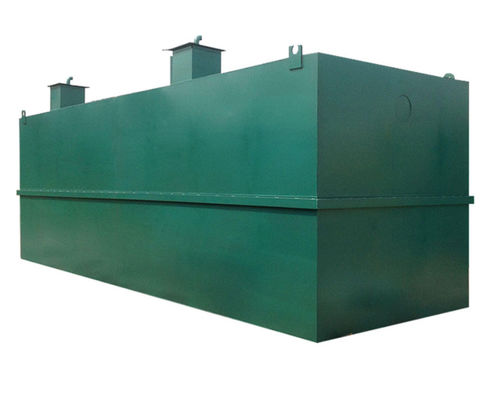

Containerized MBBR Wastewater Treatment Plant Manufacturers

Product Description

The core of the MBBR process is to realize the full fluidization of the suspended carrier filler to achieve the purpose of strengthening the treatment of pollutants. In the actual application of the MBBR process, the main factors that need to be considered are the type of the biochemical tank, the dosage of suspended fillers, the aeration system, the interception screen, and the propeller.

The effluent quality can meet Class I A/B standard Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002) or Class IV Standard of Environmental Quality Standards for Surface Water (GB3838-2002).

Features

1. The fluidization of the biological filler in the aeration zone is the key to the system to achieve a good processing function.

2. It is mainly realized by the aeration system of the aerobic zone of the biochemical tank. An appropriate aeration system in the aerobic zone can ensure the fluidization effect of the biological carrier fluidized filler, ensure that the fluidized filler flows up and down and back and forth in the water body, so that the filler and sewage can be fully mixed, collided, and contacted, which is effective Complete the three-way contact, exchange, and adsorption processes of pollutants, water and gas.

3. The specific gravity of the filler is generally selected to be 0.94-0.97. During the cultivation period, a large amount of biofilm will slowly adhere to the surface of the filler. The greater the amount of adhesion, the greater the specific gravity.

4. When the biofilm on the filler reaches a certain thickness, its specific gravity is greater than 1. The filler sinks from the non-aerated zone to the bottom of the pool. The impact force at the bottom of the aerated zone is the strongest, which can quickly wash away the residual biofilm on the filler. The specific gravity of the filler after stripping also decreases to below 1 and rises in the aeration zone.

Product Number

| Model |

Voltage |

Power |

Weight |

Size(m) |

| (V) |

(kW) |

(t) |

(L×W×H) |

| MSC-MBBR-30 |

380 |

0.78 |

4.5 |

5.3×2.5×2.9 |

| MSC-MBBR-60 |

380 |

1.38 |

7 |

7.3×2.7×2.9 |

| MSC-MBBR-75 |

380 |

1.59 |

7.5 |

8.1×2.7×2.9 |

| MSC-MBBR-100 |

380 |

2.33 |

9 |

9.2×2.7×2.9 |

| MSC-MBBR-150 |

380 |

3.03 |

13 |

13.4×2.7×2.9 |

| MSC-MBBR-200 |

380 |

3.46 |

17 |

16.5×2.7×2.9 |

MBBR equipment advantages

1. The main material of the equipment box adopts special steel plate for container, which has good anti-corrosion effect of weather-resistant steel, second only to stainless steel in anti-corrosion, and comparable to stainless steel after anti-corrosion, and has a long service life;

2. The equipment box adopts fully automatic robot welding to ensure the quality of the weld seam. The rust removal adopts fully automatic mechanical sandblasting, and the rust removal level is not lower than Sa2.5 to ensure durability;

3. The equipment box adopts the form of corrugated board, which has greatly enhanced strength, light weight, and is convenient for transportation, installation and debugging;

4. The equipment in the station is automatically controlled, and the equipment in the station can be monitored remotely, and the centralized remote monitoring of multiple stations, management, laboratory testing, and technical platforms are centralized by region;

5. Mobile APP remote monitoring and control, mobile APP remote control cloud platform, using 4G network, only need to install 4G data card, you can monitor and control the integrated equipment on the mobile phone at any time;

6. Equipment modular installation, on-site combined installation, flexible and changeable forms, suitable for transportation and installation in small space and inconvenient areas;

Application

1. Rural/township domestic sewage treatment, no municipal official website scenic area domestic sewage treatment.

2. Suitable for residential quarters, office buildings, shopping malls, hotels, restaurants, government schools, military units, factories and other domestic sewage.

3. Similar industrial organic wastewater, such as organic wastewater treatment in textile, beer, paper, leather, food, chemical and other industries.

4. Black odor water body control source interception, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!